How ‘Artificial Leaves’ Use Sunlight to Make Medicine

Researchers have built a portable, solar-powered factory that mimics a leaf, promising a revolution in making medicine and materials anywhere on Earth... or even Mars.

Key Findings

- Scientists built a self-powered "artificial leaf" that makes chemicals using only sunlight.

- The device works off-grid, even on cloudy days, by adjusting its speed in real-time.

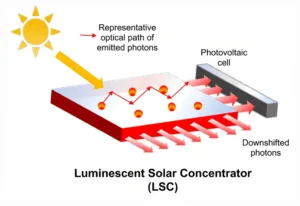

- It uses a "Luminescent Solar Concentrator" (LSC) to capture and focus specific colors of light for chemistry.

- A separate solar panel captures the "leftover" light to power the device's pumps and computer.

- This makess portable, on-demand chemical manufacturing is possible anywhere.

Primary Source

Source: Development of an off-grid solar-powered autonomous chemical mini-plant for producing fine chemicals.

Author(s): Masson, T. M. et al., led by Prof. Timothy Noël

For over a century, making chemicals has meant one thing: giant factories. These huge plants use massive amounts of fossil fuels to produce everything from medicines to plastics.1“UvA scientists develop fully solar-driven autonomous chemical mini-plant.” University of Amsterdam (2021). https://www.uva.nl/shared-content/uva/en/news/press-releases/2021/10/uva-scientists-develop-fully-solar-driven-autonomous-chemical-mini-plant.html This system is energy-intensive and not very flexible. But nature has a better model. The humble leaf does complex chemistry using only sunlight, water, and air. Scientists have dreamed of copying this for decades. That dream has been hard to achieve. The sun’s energy is spread out and inconsistent.

Now, a team led by Professor Timothy Noël at the University of Amsterdam has built a working “artificial leaf.” It is a fully autonomous, solar-powered chemical mini-reactor.2Masson, T. M. et al. “Development of an off-grid solar-powered autonomous chemical mini-plant for producing fine chemicals.” ChemSusChem (2021). https://doi.org/10.1002/cssc.202102011 This device is not just a lab experiment. It is a blueprint for a future where life-saving medicines can be made on-demand, anywhere in the world, with no power grid required.

How Does This ‘Artificial Leaf’ Actually Work?

The device is a flat square pane that looks like a sheet of red plastic. It’s called a Luminescent Solar Concentrator-PhotoMicroreactor (LSC-PM). This design brilliantly solves two problems at once: capturing sunlight and performing chemistry.

Here is the simple breakdown:

- It acts like a light antenna. The sheet is doped with fluorescent dyes that absorb sunlight (mostly blue and green light) over a large area.3“UvA scientists develop fully solar-driven autonomous chemical mini-plant.” University of Amsterdam (2021). https://www.uva.nl/shared-content/uva/en/news/press-releases/2021/10/uva-scientists-develop-fully-solar-driven-autonomous-chemical-mini-plant.html

- It converts the light. The dyes re-emit this energy as a specific color of red light. This is key. The “junk food” of mixed white sunlight is converted into the perfect “superfood” for the chemical reaction.

- It funnels the light. This red light is trapped inside the sheet and guided, like in an optical fiber, to the edges. This process concentrates the sunlight, turning a diffuse energy source into a powerful beam.4“Alternative Uses of Luminescent Solar Concentrators.” MDPI (2021). https://www.mdpi.com/2673-706X/2/3/10

- It runs a micro-factory. Tiny, thin channels are embedded inside the sheet. A liquid solution flows through these tubes. The concentrated red light shines directly on these channels, powering a photocatalyst that drives the chemical reaction.5“Applications of continuous-flow photochemistry in organic synthesis, material science, and water treatment.” Pure (2016). https://pure.tue.nl/ws/files/61909645/ChemRev_2016.pdf

This “flow chemistry” design is vital. The super-thin tubes ensure every single molecule gets blasted with the perfect amount of light. This is something impossible to do in a big, round flask.

Schematic of the optical pathway in an LSC. Credit: University of Cambridge, Dept. of Materials Science & Metallurgy

What Makes This ‘Leaf’ So Smart?

The biggest challenge for solar power is not just capturing light. It is dealing with its inconsistency. What happens when a cloud passes by? A normal solar-powered device would falter. Its chemical reaction would fail or create impure products.

The team’s solution is brilliant. The device is smart.

It has a light sensor that constantly measures the intensity of the concentrated red light. This sensor sends data to a small computer controller. When the sun dims, the controller instantly tells the pumps to slow down the flow of chemicals. This gives the molecules a longer “residence time” in the channels. They get just enough light to react perfectly. When the sun is bright, the pumps speed up to maximize production.6“Clouds defeated: real-time control system boosts solar chemicals production.” The Chemical Engineer (2021). https://www.thechemicalengineer.com/news/clouds-defeated-real-time-control-system-boos-ts-solar-chemicals-production/ This feedback loop guarantees a consistent, high-purity product. It can do this even on a cloudy day in the Netherlands, where the device was tested.7Masson, T. M. et al. “Development of an off-grid solar-powered autonomous chemical mini-plant for producing fine chemicals.” ChemSusChem (2021). https://doi.org/10.1002/cssc.202102011

Why Is This a Bigger Deal Than Just Solar Power?

This “artificial leaf” is also a complete, self-sustaining system. It needs no batteries or wall plugs. But what powers its smart controller and pumps?

The team used a “waste-not” approach. The red LSC sheet is transparent to other colors of light. It only uses the blue and green photons. So, the team placed a standard silicon solar panel directly behind it.8“Development of an off-grid solar-powered autonomous chemical mini-plant for producing fine chemicals.” Advances in Engineering (2021). https://advanceseng.com/development-grid-solar%E2%80%90powered-autonomous-chemical-mini%E2%80%90plant-producing-fine-chemicals/ This panel soaks up all the “leftover” red and infrared light that passes through. This “waste” light is converted into electricity, which powers the pumps and electronics. The system uses the entire solar spectrum with maximum efficiency.

Where Could We Use These Portable Factories?

The implications are enormous. This technology changes *where* chemistry can happen. It replaces the idea of a massive, centralized factory with a nimble, distributed network.

Imagine shipping containers of these panels sent to a disaster zone to produce essential medicines. Think of a remote village in a developing nation making its own anti-malarial drugs using only sunlight.9“Researchers create malaria medicine with solar reactor.” NWO (2018). https://www.nwo.nl/en/cases/researchers-create-malaria-medicine-with-solar-reactor This could even be a key technology for future human outposts on Mars, allowing astronauts to synthesize materials far from Earth. It promises a future of on-demand, sustainable manufacturing that is more resilient and accessible for everyone.

What Are the Next Steps?

This technology is incredibly promising, but it is still new. The researchers must test the long-term stability of the dyes and materials under constant, intense sunlight.10“Alternative Uses of Luminescent Solar Concentrators.” MDPI (2021). https://www.mdpi.com/2673-706X/2/3/10 They also need to expand its chemical “cookbook” to produce a wider range of molecules.

Still, this breakthrough is a huge step. It fulfills a century-old dream, first envisioned by chemist Giacomo Ciamician in 1912, of a “green” chemical industry powered by the sun.11“Artificial photosynthesis.” Wikipedia, accessed October 18, 2025. https://en.wikipedia.org/wiki/Artificial_photosynthesis This artificial leaf proves that small, smart, and solar-powered is the future of chemical manufacturing.